A weighting game

Every kiln 'charge' is weighed down with a slab of heavy metal which prevents the timber from changing shape as it releases moisture. Once a charge is ready, it's fed into the kiln.

Low and slow

The kilns are heated by a network of pipes that ferries hot oil throughout a drying chamber to give a high level of control over temperatures throughout the process. Clouds of white steam billow into the air as moisture leaves the timber. The steam is used to recondition the next charge of dry timber moving in the opposite direction, giving an even ~11% moisture content throughout each board.

Cooked to perfection

After travelling through the drying chamber, the charge will make the return trip for equalisation. Now dried it will be straight and stable, without twists, cupping or warping, and well on its way to becoming the good stuff.

sustainability in focus

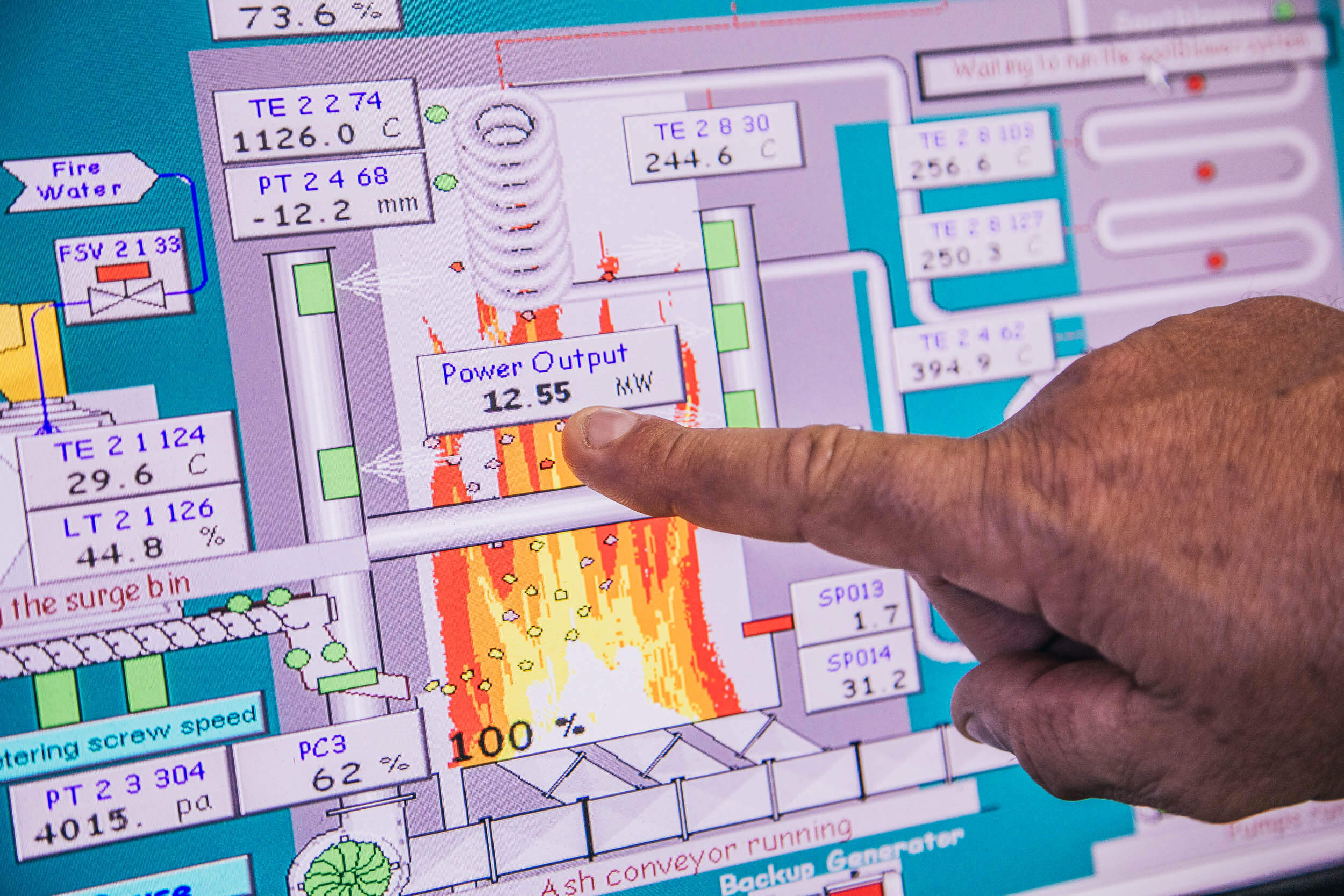

Powered by by-product

It takes a lot of energy to power a kiln, but instead of burning coal like in a steel smelter, we power our kilns with bio-fuel pellets made from our own sawdust. It's just one of the factors that add up to timber having one of the lowest embodied energies of all construction materials.

Good things take time

Some argue it's an art, but our team argue they have it down to a fine science. Either way, there's no argument the kiln-drying process is the biggest bottleneck in any mill, and for many of our competitors the temptation to rush the process is too great. We take that little bit extra time to ensure we get the science right... because that little extra care means a whole lot extra durability.