From little things…

These little guys are in fact an advanced hybrid of the Southern Pine and will one day grow to become a diverse array of products ranging from house framing and glue-laminated beams to landscaping products and paper.

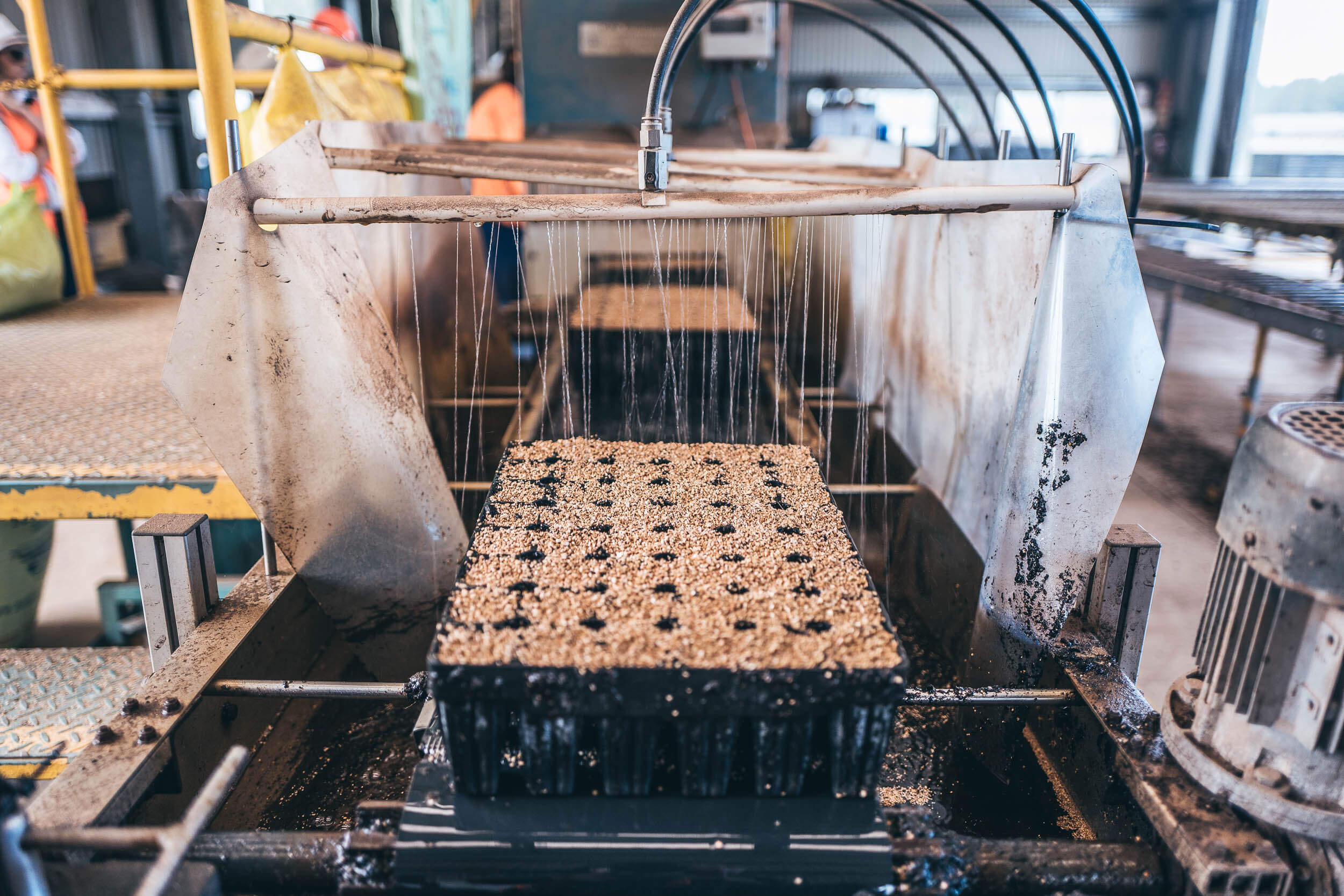

Into the sowing machine

Each tray moves steadily along a conveyor belt, first through a tiller before passing the watchful eye of the team. Because it might take a machine to sow over 10 Million seeds per year, but no machine can replace the human touch required in caring for and raising these little ones.

The best chance in life

After a dusting of vermiculite and a drink of rainwater, each tray is ready to be moved out into netted enclosures. They’ll stay covered for their first month before growing big enough to move out into the open.

After 3 months…

By now, seedlings are perhaps better described as saplings. They’ve begun to outgrow their pots, and are ready to take root in solid ground.

Sorting and packing

Before they hit the plantation, the team sifts through thousands upon thousands of saplings, assessing each individual for health and conformation before being handed over to the planting team.

focus on sustainability

Resourceful from the very beginning

No resource is wasted, with pine bark from the Mill being recycled into the potting mix used to plant seedlings. As for the seeds themselves, they come from our own pine cones of course, which are in turn watered using harvested rainwater.